Anilox

Okay kiddo, have you ever heard of printing? It's when you put ink on paper or other materials to make pictures and words. But have you ever wondered how the ink gets onto the printing press in the first place?

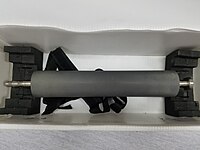

That's where something called an anilox roller comes in. The anilox roller is kind of like a big cylindrical sponge – except it's not really a sponge and it doesn't soak up anything. Instead, it has lots of tiny little holes or cells on its surface that hold just the right amount of ink for printing.

When the printing press rolls over the anilox roller, the ink from the cells transfers onto the press, which then uses it to create the images and text you see on paper or other materials. The anilox roller makes sure that the ink is evenly distributed and is the right thickness to create clear, crisp prints.

The anilox roller is really important for printing because it allows for precise control over the amount of ink that's put on the press. Too little ink and the prints will look faint and blurry. Too much ink and the prints will look smudged and messy. So, the anilox roller helps make sure that the prints look just right.

That's pretty much it, kiddo! The anilox roller is an important tool used in printing to make sure that the ink is distributed evenly and in just the right amount to create great prints.

That's where something called an anilox roller comes in. The anilox roller is kind of like a big cylindrical sponge – except it's not really a sponge and it doesn't soak up anything. Instead, it has lots of tiny little holes or cells on its surface that hold just the right amount of ink for printing.

When the printing press rolls over the anilox roller, the ink from the cells transfers onto the press, which then uses it to create the images and text you see on paper or other materials. The anilox roller makes sure that the ink is evenly distributed and is the right thickness to create clear, crisp prints.

The anilox roller is really important for printing because it allows for precise control over the amount of ink that's put on the press. Too little ink and the prints will look faint and blurry. Too much ink and the prints will look smudged and messy. So, the anilox roller helps make sure that the prints look just right.

That's pretty much it, kiddo! The anilox roller is an important tool used in printing to make sure that the ink is distributed evenly and in just the right amount to create great prints.