Blow molding

Have you ever blown bubbles with a straw in your drink? Blow molding works sort of like that, but instead of making bubbles, it makes things like bottles and containers.

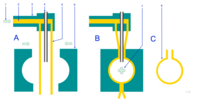

First, a special machine takes a chunk of plastic and melts it down into a liquid. Then, it puts the liquid into a special mold. The mold is a shape that is the same as the thing we want to make, like a bottle.

Next, the machine puts a long tube into the liquid plastic in the mold. This tube is called an "extruder". The extruder pushes air into the mold through the tube. The air blows the melted plastic back and stretches it out until it fills the whole shape of the mold.

When it's all filled out and cool, the machine takes the new bottle or container out of the mold. Then, it can be labeled and shipped off to the store for you or me to buy!

First, a special machine takes a chunk of plastic and melts it down into a liquid. Then, it puts the liquid into a special mold. The mold is a shape that is the same as the thing we want to make, like a bottle.

Next, the machine puts a long tube into the liquid plastic in the mold. This tube is called an "extruder". The extruder pushes air into the mold through the tube. The air blows the melted plastic back and stretches it out until it fills the whole shape of the mold.

When it's all filled out and cool, the machine takes the new bottle or container out of the mold. Then, it can be labeled and shipped off to the store for you or me to buy!