Blow moulding

Blow molding is a process used to make things like water bottles, milk jugs, and shampoo bottles. It's called "blow" molding because air is used to create the shape of the bottle. Think about blowing up a balloon until it's the size and shape you want - that's kind of what happens in blow molding.

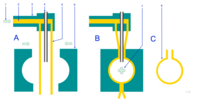

Here's how it works. First, a special kind of plastic called thermoplastic is melted down into a liquid form. This liquid is then put into a machine called an extruder that shapes the plastic into a long tube called a parison. The parison looks kind of like a skinny hotdog.

The parison is then placed into a mold that's the shape of the final product. The mold has two halves that fit together like a puzzle. Air is then blown into the parison, causing it to expand to fill the mold. The air also helps cool the plastic so that it hardens in the shape of the mold.

Once the plastic is hard, the mold is opened and the finished product is removed. The excess plastic on the top and bottom of the product is trimmed off, and any decorations or labels are applied.

Overall, blow molding is a cool process used to make many of the plastic products we use every day!

Here's how it works. First, a special kind of plastic called thermoplastic is melted down into a liquid form. This liquid is then put into a machine called an extruder that shapes the plastic into a long tube called a parison. The parison looks kind of like a skinny hotdog.

The parison is then placed into a mold that's the shape of the final product. The mold has two halves that fit together like a puzzle. Air is then blown into the parison, causing it to expand to fill the mold. The air also helps cool the plastic so that it hardens in the shape of the mold.

Once the plastic is hard, the mold is opened and the finished product is removed. The excess plastic on the top and bottom of the product is trimmed off, and any decorations or labels are applied.

Overall, blow molding is a cool process used to make many of the plastic products we use every day!