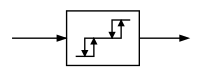

Double-setpoint control

Double-setpoint control is a way of controlling a machine or process that has two different goals it needs to achieve. Imagine you're baking a cake, and you need the temperature in your oven to be 350 degrees to bake the cake properly. But you also need to make sure the oven doesn't get too hot and burn the cake.

Double-setpoint control works by setting two different "setpoints" or targets for the machine or process to aim for. In the case of baking a cake, you would set one setpoint for the desired baking temperature of 350 degrees, and another setpoint for the maximum temperature you want to reach to prevent the cake from burning.

The machine or process then measures the current temperature and adjusts its behavior depending on how far it is from these two setpoints. If the temperature is too low, it will apply more heat to reach the desired baking temperature setpoint. If the temperature is getting too high, it will start to reduce the amount of heat applied to prevent exceeding the maximum temperature setpoint.

In simpler terms, think of it like playing a game of "hot and cold." You adjust your behavior based on whether you are getting closer or farther away from the desired setpoints.

Double-setpoint control is important in many industries, such as food processing, heating, and cooling, as it helps to ensure consistent product quality and safety by maintaining tight control over process variables.

Double-setpoint control works by setting two different "setpoints" or targets for the machine or process to aim for. In the case of baking a cake, you would set one setpoint for the desired baking temperature of 350 degrees, and another setpoint for the maximum temperature you want to reach to prevent the cake from burning.

The machine or process then measures the current temperature and adjusts its behavior depending on how far it is from these two setpoints. If the temperature is too low, it will apply more heat to reach the desired baking temperature setpoint. If the temperature is getting too high, it will start to reduce the amount of heat applied to prevent exceeding the maximum temperature setpoint.

In simpler terms, think of it like playing a game of "hot and cold." You adjust your behavior based on whether you are getting closer or farther away from the desired setpoints.

Double-setpoint control is important in many industries, such as food processing, heating, and cooling, as it helps to ensure consistent product quality and safety by maintaining tight control over process variables.