Pulse jet engine

A pulse jet engine is like a magic whistle that can make a continuous sound with no moving parts. Imagine taking a big straw, like the ones you use for drinking soda, and blowing air through it. You would hear the sound of the air rushing through the straw. Now imagine that instead of blowing air through the straw, you light a small flame at one end. The flame heats up the air inside the straw and makes it expand rapidly, creating a burst of energy that shoots out the other end of the straw like a puff of smoke.

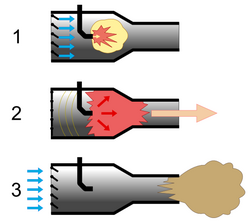

This is basically how a pulse jet engine works. Inside the engine, there is a tube with a spark plug that ignites a fuel/air mixture at one end. The explosion created by the spark plug heats up the air inside the tube, which expands rapidly and shoots out the other end of the tube like a burst of energy. This creates a pulse or shock wave that travels down the tube, sucking in more fuel/air mixture behind it.

As the fuel/air mixture enters the tube, it mixes with the residual heat left behind from the combustion process, which ignites the next pulse. This creates a continuous cycle of combustion, expansion, and thrust that powers the engine.

Some pulse jet engines use a series of tubes that are connected in parallel, which allows for more fuel/air mixture to be burned at once and produces a more powerful thrust. Others use a single tube with a reed valve that allows air to flow in and out, creating a more efficient and quieter operation.

Overall, pulse jet engines are a simple and inexpensive way to create thrust and power small aircraft, hobby vehicles, and even fireworks. However, they are not as efficient or reliable as other types of jet engines, and can be quite noisy and dangerous if not properly constructed and operated.

This is basically how a pulse jet engine works. Inside the engine, there is a tube with a spark plug that ignites a fuel/air mixture at one end. The explosion created by the spark plug heats up the air inside the tube, which expands rapidly and shoots out the other end of the tube like a burst of energy. This creates a pulse or shock wave that travels down the tube, sucking in more fuel/air mixture behind it.

As the fuel/air mixture enters the tube, it mixes with the residual heat left behind from the combustion process, which ignites the next pulse. This creates a continuous cycle of combustion, expansion, and thrust that powers the engine.

Some pulse jet engines use a series of tubes that are connected in parallel, which allows for more fuel/air mixture to be burned at once and produces a more powerful thrust. Others use a single tube with a reed valve that allows air to flow in and out, creating a more efficient and quieter operation.

Overall, pulse jet engines are a simple and inexpensive way to create thrust and power small aircraft, hobby vehicles, and even fireworks. However, they are not as efficient or reliable as other types of jet engines, and can be quite noisy and dangerous if not properly constructed and operated.

Related topics others have asked about: