Electron beam texturing

Imagine you have a toy car and you want to make it look cool with some designs on its surface. Electron beam texturing is a way to do this on a much smaller scale, like in a factory that makes car parts or other metal objects.

So how does it work? Well, first you need an electron gun. This is like a tiny, powerful flashlight that shoots beams of electrons instead of light. The electrons are really small particles that are too small for us to see, but they can do some cool things when you aim them at metal.

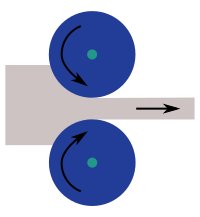

Next, you need a metal surface that you want to put a design on. This surface is put in a machine that is kind of like a miniature mountain range, with hills and valleys (or bumps and grooves) on its surface. When the electron gun shoots its beam at this surface, the electrons collide with the metal and cause it to become heated up and melted. The metal then cools down and hardens, forming small bumps and grooves around where the electron beam hit it.

By controlling how the electron beam moves across the surface, you can make all sorts of designs and patterns in the metal. These designs can be very precise and detailed, just like drawing with a pen or paintbrush.

Electron beam texturing is used in many industries to improve the performance and appearance of metal parts. For example, it can be used on car engines to make them run smoother and more efficiently, or on airplane wings to help them reduce drag and fly faster. It can also be used to give metal objects a decorative finish, to make them look more interesting or stylish.

So how does it work? Well, first you need an electron gun. This is like a tiny, powerful flashlight that shoots beams of electrons instead of light. The electrons are really small particles that are too small for us to see, but they can do some cool things when you aim them at metal.

Next, you need a metal surface that you want to put a design on. This surface is put in a machine that is kind of like a miniature mountain range, with hills and valleys (or bumps and grooves) on its surface. When the electron gun shoots its beam at this surface, the electrons collide with the metal and cause it to become heated up and melted. The metal then cools down and hardens, forming small bumps and grooves around where the electron beam hit it.

By controlling how the electron beam moves across the surface, you can make all sorts of designs and patterns in the metal. These designs can be very precise and detailed, just like drawing with a pen or paintbrush.

Electron beam texturing is used in many industries to improve the performance and appearance of metal parts. For example, it can be used on car engines to make them run smoother and more efficiently, or on airplane wings to help them reduce drag and fly faster. It can also be used to give metal objects a decorative finish, to make them look more interesting or stylish.

Related topics others have asked about: