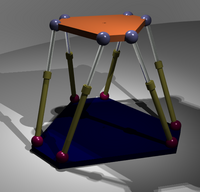

Parallel manipulator

Have you ever played with a toy with two moving parts that can both move in different directions at the same time? That's kind of like what a parallel manipulator is, but on a much bigger and fancier scale.

A parallel manipulator is a robot arm that has two or more main arms that move in parallel to each other. This means that they move in the same direction and at the same time. The arms are connected to a base, which is where the robot is attached to the ground or to a machine.

The arms of a parallel manipulator are designed to be very strong and stable, so they can move heavy objects or perform precise tasks with great accuracy. They can also move very quickly and smoothly, which is important for things like assembly line robots or 3D printers.

One of the advantages of a parallel manipulator is that it can move very precisely and quickly in three dimensions (up and down, side to side, and back and forth). This makes it ideal for tasks where precision and speed are important, like manufacturing or medical procedures.

Another advantage of a parallel manipulator is that it can be very compact, which means it can fit into small spaces and work in tight quarters. This makes it useful for tasks like assembling small electronic devices or performing surgery inside the human body.

Overall, a parallel manipulator is a very complex and advanced machine, but it's kind of like a giant toy robot arm that can do incredible things with amazing accuracy and speed.

A parallel manipulator is a robot arm that has two or more main arms that move in parallel to each other. This means that they move in the same direction and at the same time. The arms are connected to a base, which is where the robot is attached to the ground or to a machine.

The arms of a parallel manipulator are designed to be very strong and stable, so they can move heavy objects or perform precise tasks with great accuracy. They can also move very quickly and smoothly, which is important for things like assembly line robots or 3D printers.

One of the advantages of a parallel manipulator is that it can move very precisely and quickly in three dimensions (up and down, side to side, and back and forth). This makes it ideal for tasks where precision and speed are important, like manufacturing or medical procedures.

Another advantage of a parallel manipulator is that it can be very compact, which means it can fit into small spaces and work in tight quarters. This makes it useful for tasks like assembling small electronic devices or performing surgery inside the human body.

Overall, a parallel manipulator is a very complex and advanced machine, but it's kind of like a giant toy robot arm that can do incredible things with amazing accuracy and speed.

Related topics others have asked about: