Industrial computed tomography

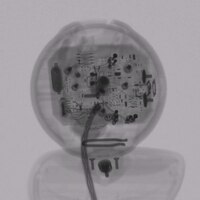

Industrial computed tomography (CT) is a fancy way of taking pictures of things from different angles to create a 3D image of the object. It's like being on a ride and going around something to see it from all sides. CT machines are very big cameras that can see through things like metal or plastic to show what's inside.

These machines have a spinning tube that revolves around the object taking many pictures at different angles while shooting tiny x-rays through the object. These pictures are then put together by a computer to create a 3D image of the object, which is very detailed and can show you things that you can't see on the surface.

Industrial CT is commonly used in different fields like automotive, aerospace, and medicine for quality control, product design, and research purposes. For example, engineers may use industrial CT to inspect a car's engine parts to see any possible defects or inspect airplane parts to make sure they are safe for flying. Doctors may use a similar technology to check bones or organs inside the human body without cutting the skin.

In short, industrial computed tomography is like taking an x-ray picture but from many angles and creating a 3D image of the object to find problems or study its internal structure.

These machines have a spinning tube that revolves around the object taking many pictures at different angles while shooting tiny x-rays through the object. These pictures are then put together by a computer to create a 3D image of the object, which is very detailed and can show you things that you can't see on the surface.

Industrial CT is commonly used in different fields like automotive, aerospace, and medicine for quality control, product design, and research purposes. For example, engineers may use industrial CT to inspect a car's engine parts to see any possible defects or inspect airplane parts to make sure they are safe for flying. Doctors may use a similar technology to check bones or organs inside the human body without cutting the skin.

In short, industrial computed tomography is like taking an x-ray picture but from many angles and creating a 3D image of the object to find problems or study its internal structure.

Related topics others have asked about: