Injection moulding

Injection moulding is like playing with Play-Doh! You know how you can make shapes by pressing the Play-Doh into a mold, and then taking it out when it's dry? Injection moulding is kind of like that, but with plastic!

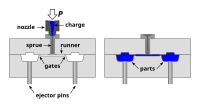

First, a big machine melts plastic pellets together until they're soft and gooey. Then, the melted plastic is injected into a special mold that's shaped like the toy or object you want to make. The mold is closed up tight so the plastic can cool and harden inside.

Once the plastic is cool and hard, the mold is opened up and the finished toy or object comes out. Just like you can make lots of different shapes with Play-Doh, you can make all sorts of things with injection moulding – from plastic toys to car parts to medical supplies!

It's a really important process because it lets us make lots of things really quickly and efficiently. Plus, we can use lots of different types of plastic to make all sorts of objects – so next time you see a plastic toy or gadget, remember it might have been made with injection moulding!

First, a big machine melts plastic pellets together until they're soft and gooey. Then, the melted plastic is injected into a special mold that's shaped like the toy or object you want to make. The mold is closed up tight so the plastic can cool and harden inside.

Once the plastic is cool and hard, the mold is opened up and the finished toy or object comes out. Just like you can make lots of different shapes with Play-Doh, you can make all sorts of things with injection moulding – from plastic toys to car parts to medical supplies!

It's a really important process because it lets us make lots of things really quickly and efficiently. Plus, we can use lots of different types of plastic to make all sorts of objects – so next time you see a plastic toy or gadget, remember it might have been made with injection moulding!

Related topics others have asked about:

Craft,

Design of plastic components,

Direct injection expanded foam molding,

Extrusion moulding,

Fusible core injection moulding,

Gravimetric blender,

Hobby injection moulding,

Injection mould construction,

Matrix moulding,

Multi-material injection moulding,

Reaction injection moulding,

Rotational moulding